- For Enquiries Please Contact

- +97155 739 2020

- info@construction-power.com

Generator Repair Scenarios: How to Respond to Emergency Situations?

Emergency Power Solutions: Are Diesel Generators Your Best Bet?

May 17, 2024

Step-by-Step Guide to Operating a Rented Rigid Pipe Threader

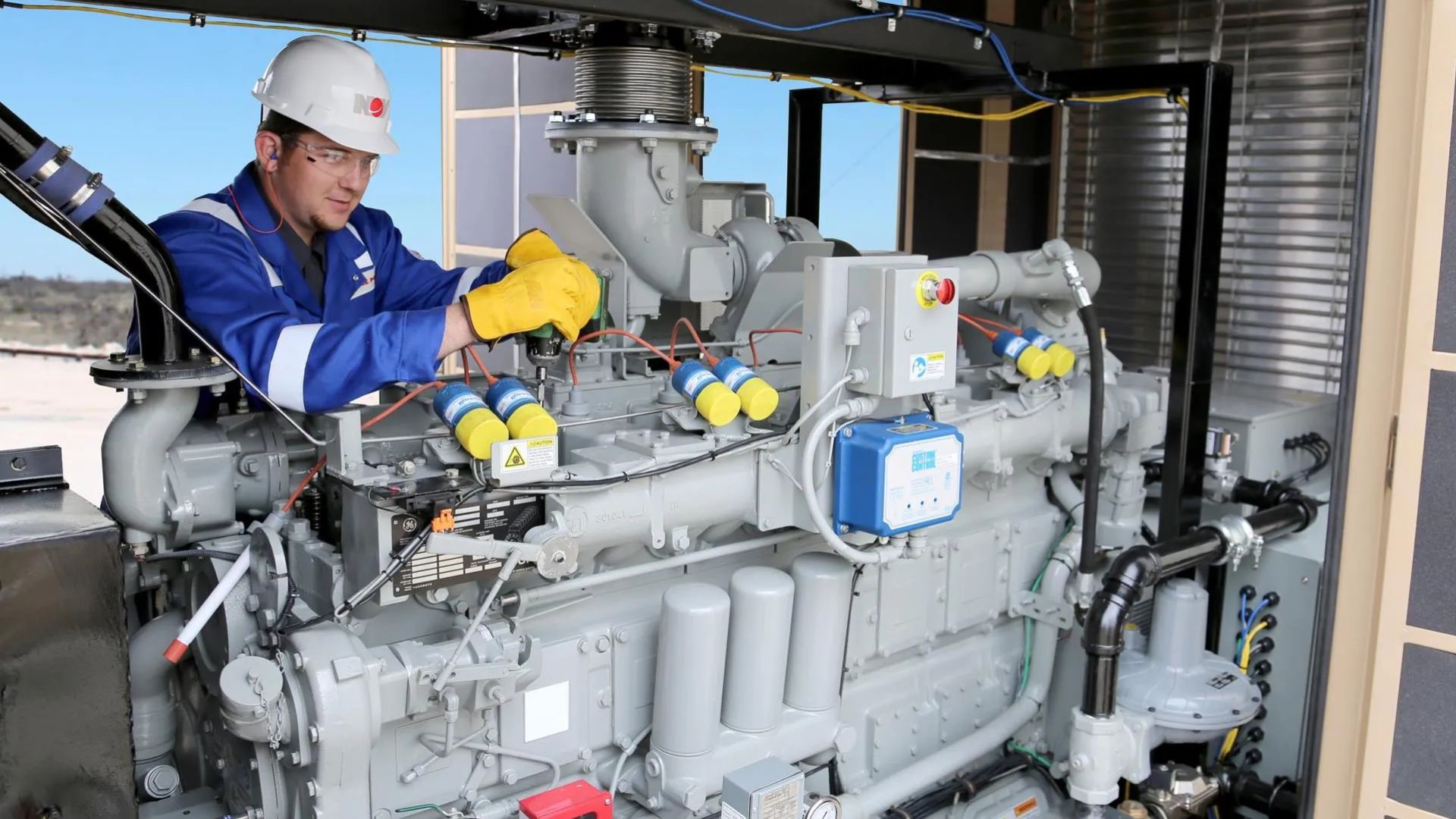

June 9, 2024In the construction industry, having a reliable power source is essential. At Construction Power, we understand the importance of maintaining continuous operations, which is why we provide not only rental generators but also essential repair and maintenance services. In this blog, we will discuss common Generator Repairs and Maintenance scenarios and how to effectively respond to these emergencies, ensuring your projects run smoothly without unexpected interruptions.

Understanding the Importance of Generator Repairs and Maintenance

Generators are the backbone of many construction projects, providing the necessary power to keep operations running smoothly. Regular maintenance and prompt repairs are crucial to prevent downtime and ensure safety on the job site. Here are some common generator repair scenarios and how to handle them effectively:

-

Sudden Generator Failure

Scenario: Your generator suddenly stops working in the middle of an operation.

Response:

- Initial Assessment: Check the fuel level, oil, and coolant levels. Often, a simple refill can resolve the issue.

- Inspect for Obvious Issues: Look for any visible signs of damage or wear, such as loose wires or leaks.

- Restart Protocol: Follow the manufacturer’s restart procedure. If the generator fails to start, it may require professional repair.

- Overheating Issues

Scenario: The generator overheats and shuts down automatically.

Response:

- Cooling System Check: Ensure that the cooling system is functioning properly. Clean any blockages in the radiator and check coolant levels.

- Ventilation: Make sure the generator is in a well-ventilated area to prevent overheating.

- Professional Inspection: If overheating persists, a thorough inspection by a qualified technician is necessary to identify and fix underlying issues.

- Electrical Malfunctions

Scenario: The generator is running but not supplying power.

Response:

- Circuit Breaker Check: Ensure the circuit breaker is not tripped. Reset it if necessary.

- Connection Inspection: Verify that all cables and connections are secure and not damaged.

- Load Management: Avoid overloading the generator. Distribute the load evenly to prevent electrical issues.

-

Fuel System Problems

Scenario: The generator is not starting due to fuel issues.

Response:

- Fuel Quality: Use high-quality fuel and ensure it is clean and free from contaminants.

- Fuel Line Inspection: Check for any blockages or leaks in the fuel line. Clean or replace the fuel filter if necessary.

- Priming the System: Prime the fuel system to remove any air pockets that might be causing starting issues.

-

Battery Failures

Scenario: The generator won’t start due to a dead battery.

Response:

-

Battery Check: Inspect the battery terminals for corrosion and clean them if needed.

-

Charge or Replace: Charge the battery or replace it if it is old or unable to hold a charge.

-

Regular Maintenance: Regularly check and maintain the battery to avoid unexpected failures.

Preventive Measures to Ensure Generator Reliability

- Regular Inspections: Conduct routine inspections to identify and address potential issues before they become major problems.

- Scheduled Maintenance: Follow the manufacturer’s maintenance schedule, including oil changes, filter replacements, and system checks.

- Professional Servicing: Hire qualified technicians for thorough inspections and repairs to ensure the generator is in optimal condition.

- Emergency Preparedness: Have a plan in place for generator failures, including access to rental units and quick-response repair services.

Conclusion

At Construction Power, we prioritize the reliability and efficiency of your power solutions. Our expert team is equipped to handle any generator repair scenario, ensuring minimal downtime and maximum productivity. By understanding common generator issues and knowing how to respond, you can maintain a seamless operation on your construction site. For more information on our services, including rental generators, core cutting, and more, visit our website or contact us directly.